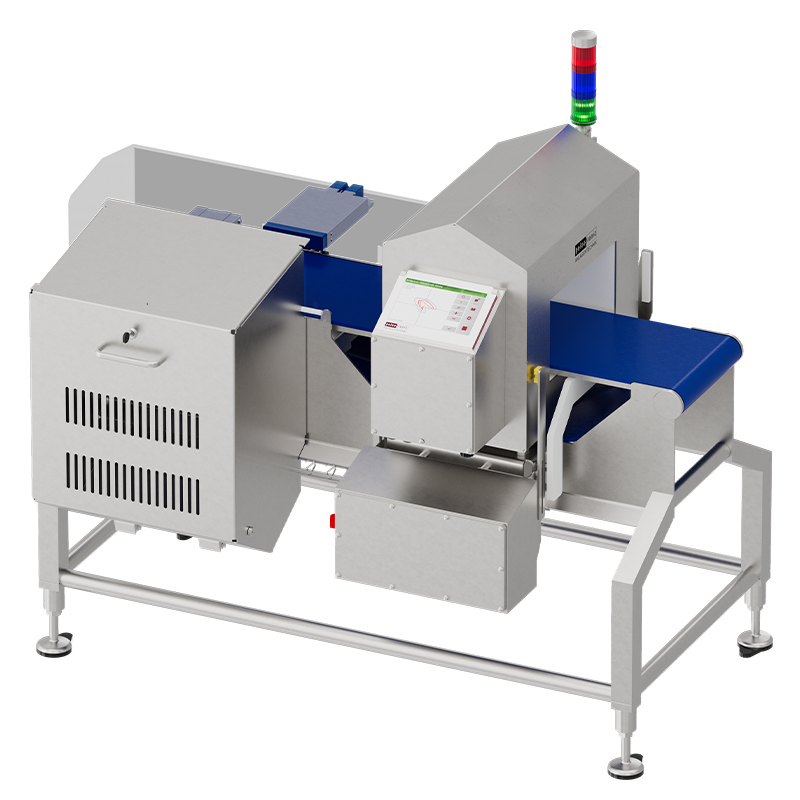

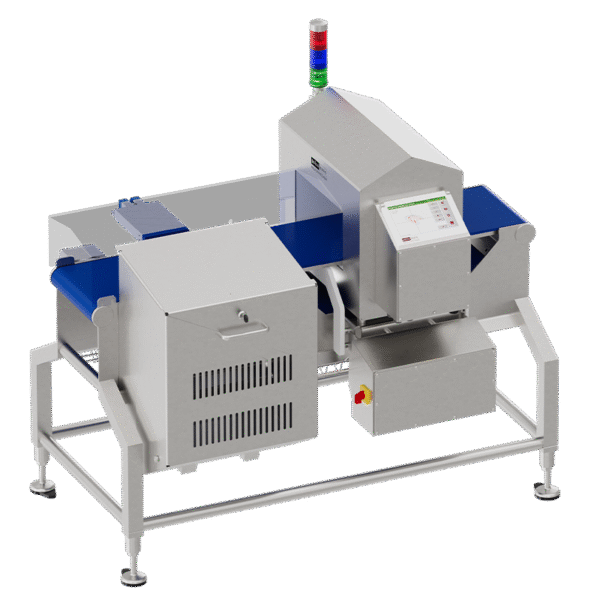

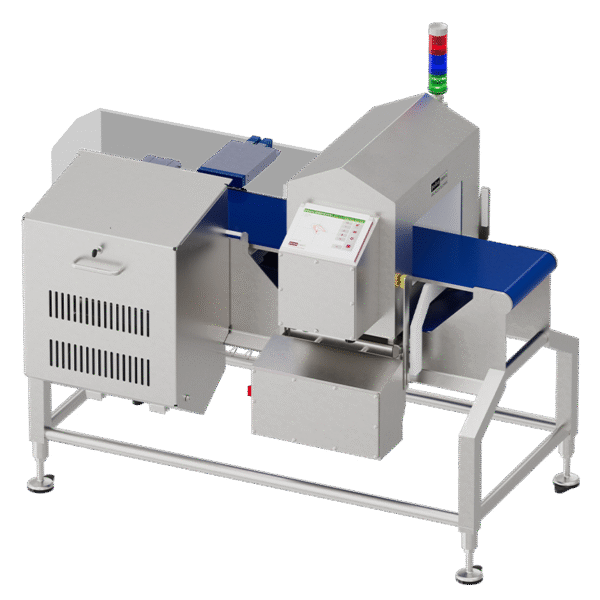

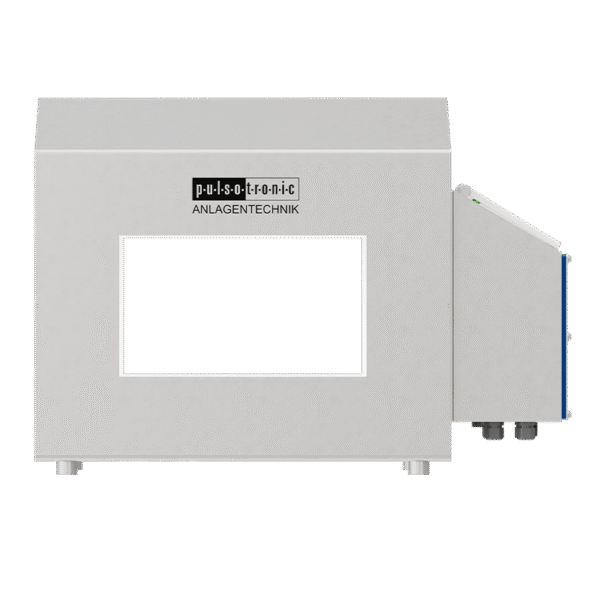

BD M-Pulse2pro / M-Pulse3

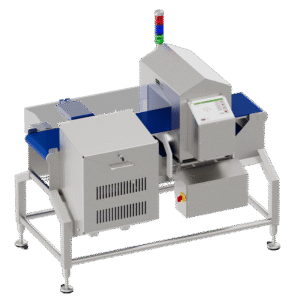

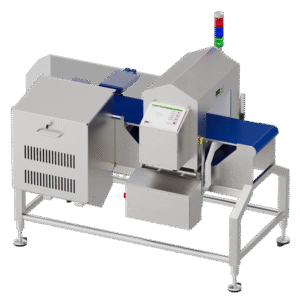

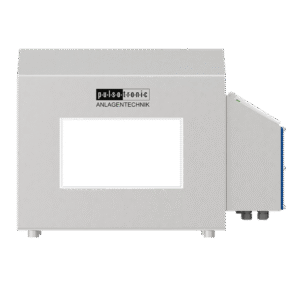

Metal detector for installation in conveyor belts

- Highest metal detection performance with multi-simultaneous-frequency technology / multiscan technology

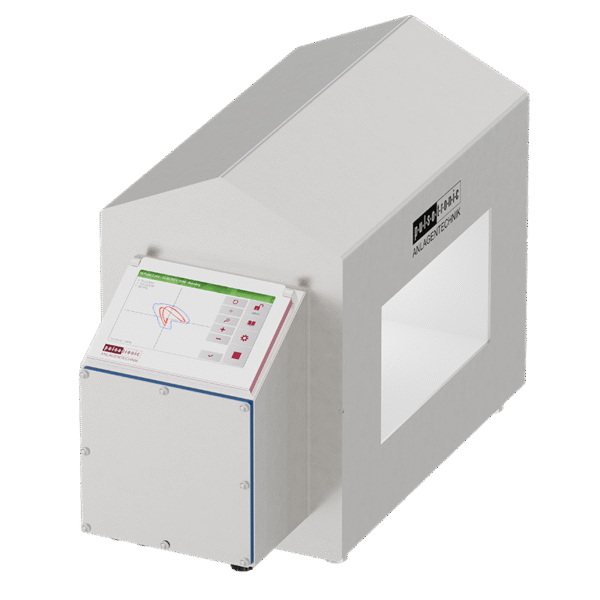

- User-friendly control unit with M-PULSE 3 for reliable, safe, and easy operation

- Audit-safe – Complies with all the established rules and standards for use in the food industry

- Rapid return on investment due to quick and intuitive operation and reliable detection

- Deskripsi

- Brand

- Peformance Features

- Application

- Function

- Equipment & specific characteristics

Deskripsi

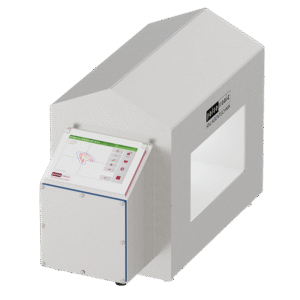

M-Pulse3 uses the multi simultaneous frequency technology in order to meet the highest requirements of the foodstuffs industry. This guarantees the best possible detection results with optimum product effect fade-out. The hygienic design and high protection class (up to IP69K) are optimally adapted to applications in the foodstuffs industry. An integrated message memory, a user management system, digital interfaces and much more come, of course, as standard!

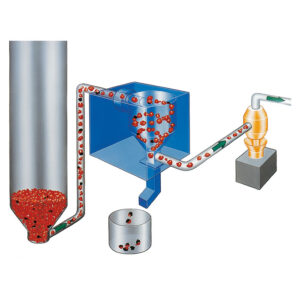

high level of detection since the magnetic field surrounds the products

- multi-simultaneous frequency technology available

- touch screen / graphical display 7“ / detached

- high-precision product effect offsetting

- unlimited product memory spaces

- Network / Ethernet / USB / remote control/support

- comprehensive support for peripherals

- optionally available in multi-frequency technology

- stainless steel housing with long-time stable and water-tight encapsulation

- available in various detector sizes, adapted for the product

- fulfills all the requirements according to HACCP / IFS

- hygienic design

- many sizes available

Tunnel detectors are used where high detection capacity and reliability are requested. For operation the user chooses among various operating electronics according to his application. Thus even complex tasks can be realised. The stainless steel housing and the smoothly grouting are the advantages making this sensor first class for the use in the food industry. Products with conductive components can be faded out easily due to modern digital technology. The sensors are maintenanceand calibration free.

Our latest generation features the so-called multi simultaneous frequency technology (MST). The products are scanned using several frequencies simultaneously before processing the data in parallel and in real time. Previous multi-frequency technologies were only able to switch between single frequencies. This was a compromise. Just like all other detectors from Pulsotronic, the M-Pulse3 requires no maintenance! Important parameters are monitored permanently by the electronics (self-diagnosis) and analysed for deviations. This makes it possible to eliminate calibration measures, downtimes and even loss of production. The wide range of interfaces allows a seamless integration of the controller into any production environment. All events are logged and can be evaluated in accordance with HACCP, ISO or IFS.

The modular electronic system is characterised by a high reliability, maximum sensitivity and a low power consumption. The intuitive user interface clearly displays important information at a large 7” display and simplifies operation. Language settings and options can be adjusted for each individual user. Due to the authentication by RFID password entries and mangement belong to history! Only authorised users have access to the controller. Set-up and daily routines are simplified by wizards. Optional it is possible to set direct support by remote maintenance. The flexible operating concept allows to use the system in all imaginable applications. It is supported by an extensive equipment of hardware, software and accessories. A wide range of variations is available to connect the electronics to it´s environment. These range from simple I/Os right through to full-scale embedding using the network interfaces (Ethernet, OPC-UA, IoT).